A premium relationship

Enjoy all year from discounts on the prices online.

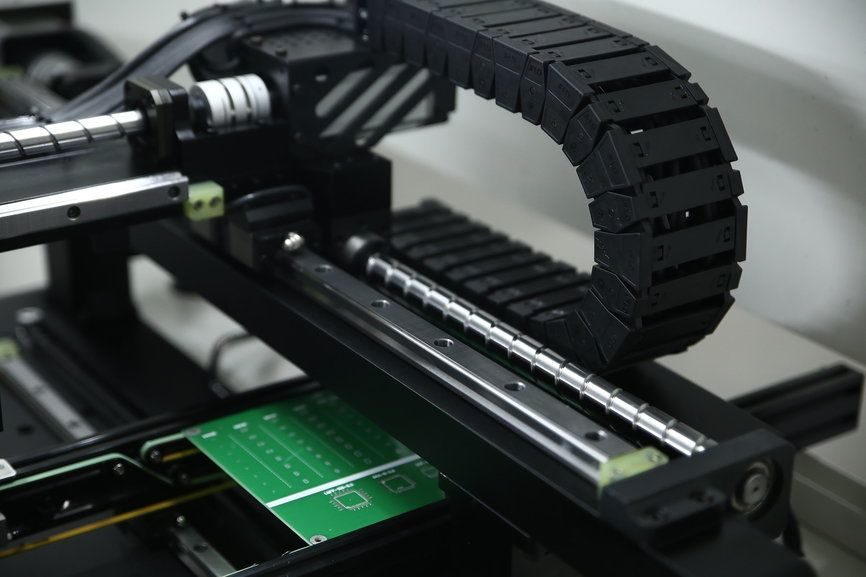

At ATF all working stations are however designed ergonomically. But the ergonomic degree is to be defined by the customer: e. g. the conveyor might be elevated by 15° towards the operator to have a better view on the pcb or for easier assembly. Just in front of the wave soldering machine, the carriers are lowered to the horizontal position.

The diversity ranges from simple conveyor systems bringing the carrier back to the beginning of the wave soldering machine to complex lines with working stations for several people.

By combining single wave soldering machines with peripheral systems it becomes a powerful assembly line individually designed for customized applications in which the solution is defined by the requirements.

As another example the manufacturing of HF-tuners might be mentioned. These are the size of 4 x 6 cm and can’t be processed by means of a carrier or finger conveyor since the solder pads are just at the edge of the pcb and next to the casing. For this purpose ATF has developed a conveyor which neither uses carriers, masks nor finger conveyor for transporting the assemblies through the fluxer unit, preheating and wave section.

Individually designed peripheral systems increase the efficiency. But the most suitable solution for your production environment must be developed individually and together.

We can help your business work even more smoothly by making you benefit from our synergy.

A premium relationship

Enjoy all year from discounts on the prices online.

A privileged contact

We advise you and accompany you throughout your industrial project.

Continuing training

We provide consulting, installation and training of all our products.

Human technology

We love technology, but we especially like to keep a human vision of industrial processes.